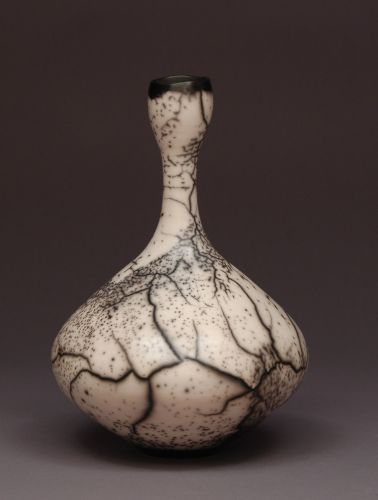

Naked Raku

The process of naked raku

Naked Raku is a variation derived from Western Raku firing techniques but differs in that these smoked pieces are unglazed.

Each piece is burnished (polished) after throwing which achieves a smooth, silky surface. It is allowed to dry completely and several layers of a fine, liquid slip called Terra Sigillata are applied and polished again after each coat. It is then fired to 950 degrees Centigrade. Following the initial firing, the piece is coated with a thick layer of slip, dried, then a crackle glaze layer is added. The slip acts as a barrier or "resist" layer which prevents the melted glaze from adhering to the piece so that the slip and glaze will separate from the clay surface after firing.

The piece is fired in a small propane kiln to 850 degrees Centigrade, removed from the kiln, "red-hot" and placed in a metal container with combustibles such as straw, sawdust or newspaper. The fracturing action of the slip and glaze layers, when penetrated by the smoke, leaves both striking and subtle patterns of dark, smoked lines on the white clay surface. Often, the pieces are fired several times to achieve a desired effect.

To protect the surface of the pots, each piece is given a light coating of wax and may be wiped with a damp cloth when necessary. These pots are not designed to hold water.